The technical and innovation area of COMSA Industrial has developed software that makes it possible to verify that construction materials created in a production line meet their size and shape specifications. The tool is applicable to construction elements manufactured in both wood, metal and plastic.

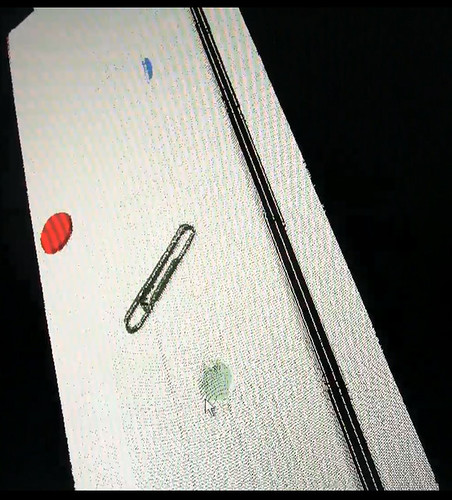

Once the item has been produced, using a laser scanner the software creates a three-dimensional model of it, which is then compared with the original template in order to detect any differences. Following this, the results are presented in the form of a three-dimensional analysis, indicating what type of problem has been found and where it is located.

The tool has already been tested in the production of wooden sections. This technological development is part of the European R&D&i R5-COP project that aims to promote the development of operating systems for robotic environments. The project, which is funded by ARTEMIS, involves the participation of companies, universities and research centres from thirteen European countries.

3D simulation made by the software of a wood profile with tare